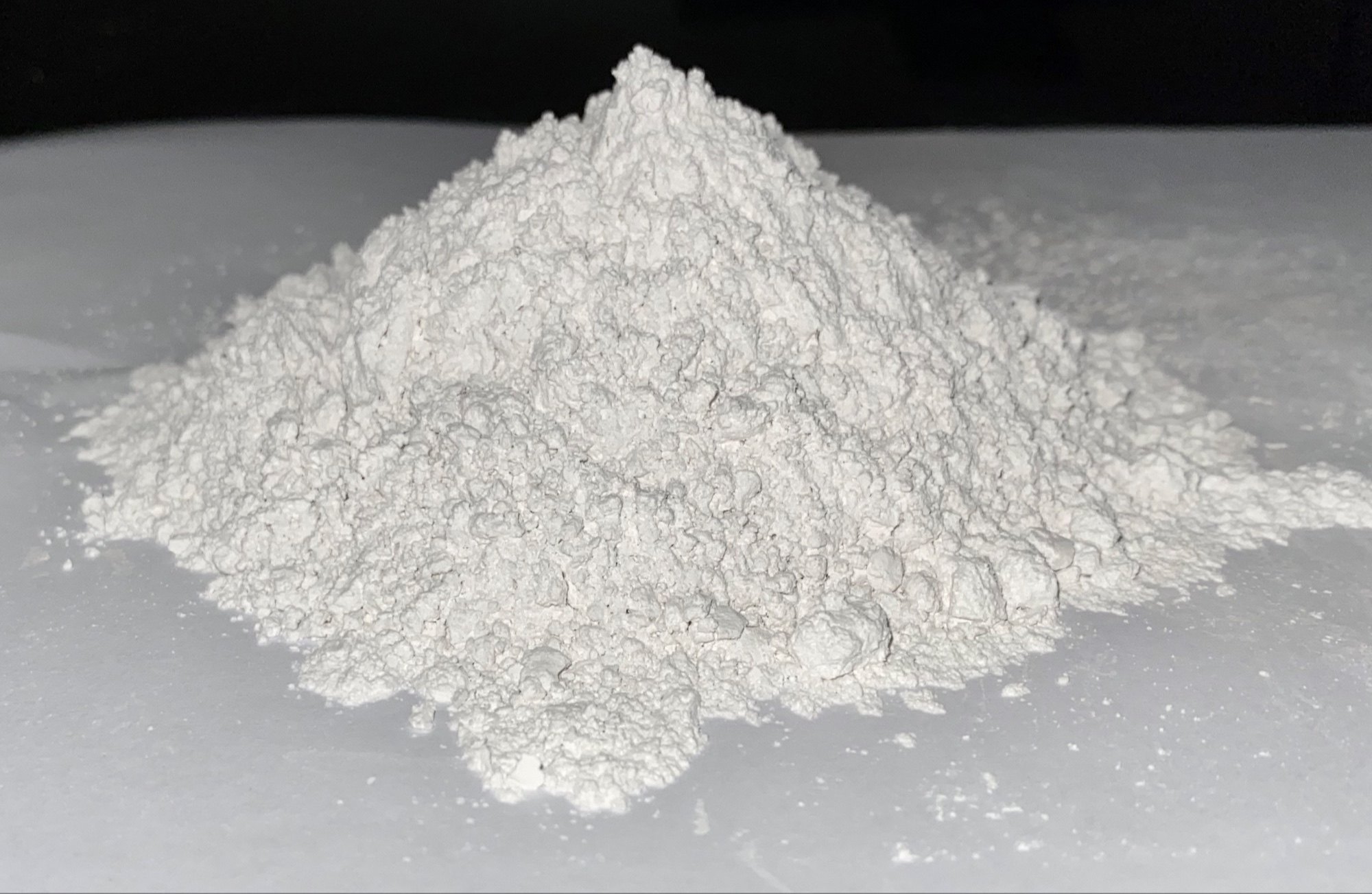

Pyrophyllite is a versatile mineral widely used in various industries, from ceramics and paints to refractories and cosmetics. To meet the growing demand for high-quality Pyrophyllite powder, it is essential for manufacturers to ensure excellence in production. By adopting expert production techniques, companies can deliver Pyrophyllite powder with the consistency, purity, and quality required to meet industry standards.

As one of the leading Pyrophyllite Powder Exporters in India, Anand Talc ensures that their products meet global standards of quality. In this article, we will explore some expert production tips to help achieve excellence in Pyrophyllite powder manufacturing, covering everything from raw material selection to quality control.

1. Sourcing the Best Raw Material

The first and most crucial step in producing high-quality Pyrophyllite powder is sourcing the right raw material. Pyrophyllite is often found in metamorphic rocks and can vary in purity depending on the geographical location of the source. To achieve consistent results in production, it’s essential to:

- Identify Premium Pyrophyllite Deposits: Look for sources with high levels of purity and minimal impurities. The mineral should be free from contaminants like iron oxides, which can affect its color and performance, especially in applications like ceramics and paints.

- Test the Raw Material: Before purchasing raw Pyrophyllite, perform thorough tests to check its chemical composition, moisture content, and particle size distribution. This ensures that the material meets the specific requirements of your target industry.

2. Proper Grinding and Pulverizing Techniques

One of the key factors that determine the quality of Pyrophyllite powder is its fineness. Different industries require different levels of fineness, so the grinding and pulverizing processes must be adapted accordingly. For example, Pyrophyllite Powder for the Ceramic Industry requires an ultra-fine powder to ensure smooth surface finishes and high mechanical strength in ceramic products.

To achieve this:

- Use Modern Grinding Equipment: Advanced grinding technology, such as jet mills and ball mills, can help achieve the ultra-fine consistency required by industries like ceramics and paints.

- Control Particle Size Distribution: It’s important to monitor and control the particle size distribution during grinding. This ensures uniformity in the final product, which is crucial for applications where consistency is key, such as in high-performance paints and ceramics.

3. Implementing Effective Quality Control Measures

Ensuring that every batch of Pyrophyllite powder meets industry standards is essential for maintaining customer satisfaction and building a reputation for reliability. Quality control measures should be integrated throughout the production process, from raw material selection to final packaging.

Some important quality control tips include:

- Regular Sampling and Testing: Regularly sample the Pyrophyllite powder at various stages of production and conduct tests to ensure it meets the required specifications. These tests can include chemical analysis, moisture content checks, and particle size measurement.

- Consistent Monitoring: Use automated systems to monitor critical production parameters in real time, ensuring consistency across batches. This is especially important for products like Pyrophyllite Powder for Paint Industry, where color consistency, particle size, and chemical composition are crucial for performance.

4. Ensuring Purity and Contaminant Removal

Impurities in Pyrophyllite powder can severely affect its performance, particularly in high-demand industries like ceramics and paints. Therefore, an effective contaminant removal process is essential. This includes:

- Magnetic Separation: Pyrophyllite may contain iron or other metallic impurities that can impact its quality. Magnetic separation is a reliable method for removing such impurities and enhancing the purity of the final product.

- Water Washing and Sedimentation: To remove soluble impurities, water washing can be an effective technique. Sedimentation can also be used to separate fine impurities based on their weight and particle size.

5. Tailoring Pyrophyllite Powder for Industry-Specific Applications

Different industries require different formulations of Pyrophyllite powder. For example, the ceramic industry requires ultra-fine powders with specific chemical compositions, while the paint industry may focus more on color consistency and ease of dispersion. By tailoring your Pyrophyllite powder to meet the exact needs of each industry, you can provide added value to your customers and establish long-term partnerships.

- Customizing Formulations: Develop customized formulations based on the end use. For example, in the paint industry, the focus may be on producing Pyrophyllite powder that enhances the smoothness and gloss of paints, while in the ceramic industry, the powder should promote vitrification and enhance thermal stability.

- Collaboration with Customers: Regularly collaborate with clients to understand their specific needs and adjust your production processes accordingly. By offering personalized solutions, you can differentiate yourself from competitors.

6. Sustainability in Pyrophyllite Powder Production

With increasing awareness of environmental sustainability, adopting eco-friendly practices in Pyrophyllite powder production is not only responsible but can also give your business a competitive edge. Consider implementing the following practices:

- Minimize Waste: Reduce waste during mining, grinding, and packaging. Implement recycling processes for by-products, such as reusing water from washing and sedimentation steps.

- Energy Efficiency: Invest in energy-efficient equipment and processes, such as solar power or low-energy grinding technologies, to reduce your environmental footprint.

- Eco-friendly Packaging: Use recyclable materials for packaging to align with growing consumer preferences for environmentally sustainable products.

7. Continuous Research and Innovation

The world of industrial minerals is ever-evolving, and staying ahead of industry trends is key to maintaining a competitive advantage. Investing in research and development can lead to new discoveries that enhance your production processes and improve the quality of your Pyrophyllite powder.

- Explore New Applications: As new technologies and materials emerge, there may be new and unexplored applications for Pyrophyllite powder. For instance, recent research shows potential for Pyrophyllite in cosmetic formulations and advanced ceramics.

- Innovate Production Techniques: Experiment with different grinding techniques, chemical treatments, and contaminant removal methods to continuously improve product quality and reduce production costs.

Conclusion

Achieving excellence in Pyrophyllite powder production requires a combination of expertise, attention to detail, and innovation. By focusing on raw material quality, precision in grinding, thorough quality control, and customization for specific industries, manufacturers can deliver top-quality Pyrophyllite powder that meets the diverse needs of customers. As a trusted Pyrophyllite Powder Exporter in India, Anand Talc is dedicated to providing superior products and pioneering sustainable practices in mineral production. With the right approach, the possibilities for high-quality Pyrophyllite powder are limitless, ensuring success in the global marketplace.