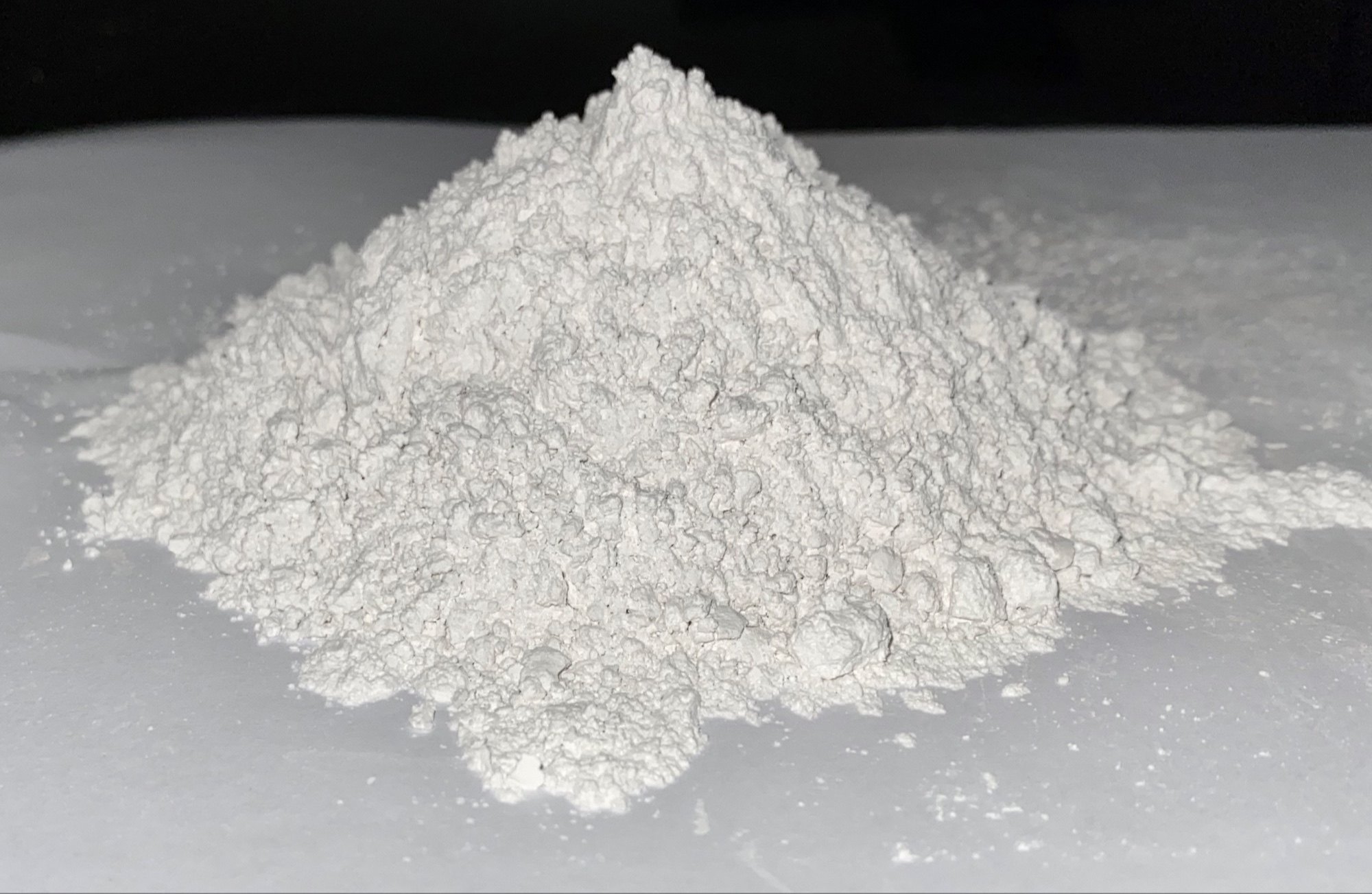

Pyrophyllite is a unique mineral widely recognized for its versatility across multiple industries. Found abundantly in metamorphic rocks, this hydrous aluminum silicate exhibits properties similar to talc, but with superior thermal stability and hardness. As a result, pyrophyllite powder has become an essential raw material for numerous industrial applications. Anand Talc, a trusted Pyrophyllite Powder exporter in India, provides high-quality solutions tailored to meet the needs of manufacturers worldwide.

What Makes Pyrophyllite Powder Special?

Pyrophyllite stands out due to its chemical composition, which includes silicon dioxide, aluminum oxide, and water. Its structure allows it to resist high temperatures and act as an excellent insulator. Additionally, it has a soft texture but is slightly harder than talc, making it ideal for applications requiring both malleability and strength. These properties make pyrophyllite powder particularly valuable in industries like ceramics, refractories, and cosmetics, among others.

Industrial Applications of Pyrophyllite Powder

1. Ceramics and Pottery

One of the largest consumers of pyrophyllite powder is the ceramics industry. Owing to its low thermal expansion and high plasticity, the mineral serves as an excellent component in creating ceramic tiles, dinnerware, and sanitary products. Pyrophyllite improves the durability and finish of ceramics, ensuring that the final products have smooth surfaces and enhanced resistance to heat and cracking.

2. Refractory Products

Pyrophyllite powder plays a vital role in the production of refractory products, which are designed to withstand extreme temperatures. Pyrophyllite Powder in Refractory Product is prized for its high heat resistance, making it an essential component in the manufacture of bricks, kiln linings, and furnace parts. Due to its excellent thermal stability, the powder prevents expansion or degradation under high heat, ensuring the longevity and effectiveness of refractory materials in steel plants and foundries.

3. Cosmetics and Personal Care Products

Pyrophyllite powder is also used in the cosmetics industry, where it serves as a substitute for talc in several skincare products. Its smooth, absorbent properties make it ideal for face powders, foundations, and body lotions. The mineral’s ability to absorb excess moisture ensures that these products remain lightweight and comfortable on the skin, while also providing a matte finish.

4. Paper and Pulp Industry

In the paper manufacturing sector, pyrophyllite powder is employed as a filler material to enhance the smoothness, printability, and opacity of paper products. By reducing the need for other chemical additives, pyrophyllite contributes to cost savings in production without compromising the quality of the final product. Its high whiteness also helps achieve better color quality in printed materials.

5. Plastics and Rubber Production

Pyrophyllite powder functions as a cost-effective filler in plastics and rubber products. Its addition improves mechanical properties, including flexibility and heat resistance, which are essential for products like automotive components, insulation materials, and industrial hoses. Furthermore, the mineral enhances the surface finish and longevity of plastic items by reducing shrinkage during the molding process.

6. Agriculture and Fertilizers

In agriculture, pyrophyllite powder is used as a soil conditioner. It helps improve soil structure, enhancing moisture retention and aeration, which benefits plant growth. Additionally, the mineral’s natural properties make it suitable for use in organic farming, where it acts as an additive in fertilizers and pesticides, promoting sustainable agricultural practices.

7. Sculpture and Artistic Works

Artists and sculptors also use pyrophyllite due to its ease of carving and smooth finish. The mineral’s fine texture allows artisans to create intricate designs without the risk of cracking or chipping. Pyrophyllite is often used to make statues, decorative objects, and even molds for casting.

8. Welding Electrodes

Pyrophyllite powder plays a crucial role in the manufacturing of welding electrodes. It helps in stabilizing the arc during welding, ensuring smooth and efficient bonding between metal surfaces. The mineral’s high thermal resistance prevents electrode degradation, resulting in more durable and reliable welding rods.

Anand Talc: Leading Exporter of Pyrophyllite Powder

Anand Talc has earned a reputation as a leading supplier of high-grade pyrophyllite powder for diverse industrial needs. Their commitment to quality and customer satisfaction ensures that manufacturers receive consistent, top-tier products that meet international standards. Anand Talc’s expertise lies not only in product delivery but also in offering customized solutions tailored to specific industrial requirements.

With extensive experience in mineral processing and an in-depth understanding of the market, Anand Talc is well-positioned to cater to industries ranging from ceramics to refractories. As a prominent Pyrophyllite Powder exporter in India, the company guarantees timely delivery, competitive pricing, and unparalleled technical support to its clients worldwide.

Conclusion

Pyrophyllite powder has emerged as a valuable mineral resource across a wide range of industries, thanks to its unique properties and adaptability. From enhancing ceramic products to fortifying refractory materials, the mineral plays a critical role in ensuring quality and performance in various applications. Anand Talc, with its expertise and reliability, continues to be a trusted partner for manufacturers seeking superior-grade pyrophyllite powder. As industries evolve and demand more efficient materials, pyrophyllite’s importance is expected to grow, cementing its status as an indispensable raw material for industrial innovation.