In today’s rapidly advancing technological landscape, efficient power distribution is crucial. Busbar trunking systems have emerged as a reliable solution for distributing electricity in commercial, industrial, and residential settings. At Manikaran, we pride ourselves on our expertise in providing top-notch installation services for busbar trunking systems. This guide will take you through the essential steps and considerations for installing these systems, ensuring a seamless and efficient process.

Understanding Busbar Trunking Systems

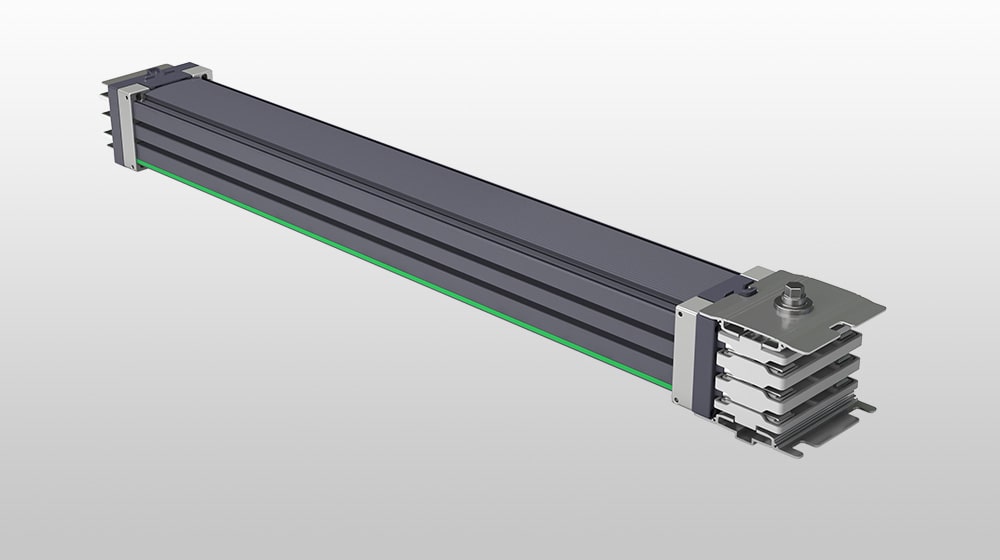

Busbar trunking systems are prefabricated electrical distribution systems that use metal busbars to conduct electricity. These systems are housed within a protective enclosure, offering a streamlined and modular approach to power distribution. The primary advantage of busbar trunking systems lies in their ability to handle high power loads while maintaining efficiency and safety.

Benefits of Busbar Trunking Systems

1. Efficiency and Reliability

Busbar trunking systems are designed to minimize energy losses, providing a highly efficient means of power distribution. The direct connection and reduced impedance paths ensure that energy is transmitted with minimal losses, leading to enhanced system reliability.

2. Flexibility and Scalability

One of the key benefits of busbar trunking systems is their flexibility. They can be easily modified or expanded to accommodate changing power needs, making them ideal for dynamic environments such as manufacturing plants and data centers. This scalability ensures that the system can grow with your business, providing long-term value.

3. Safety and Reduced Risk

Safety is a paramount concern in electrical installations, and busbar trunking systems excel in this regard. The enclosed design of the system reduces the risk of accidental contact and electrical faults. High-quality insulation materials and fire-resistant enclosures add an extra layer of protection, ensuring a safe operating environment.

4. Space Saving and Aesthetic Appeal

Busbar trunking systems are compact and take up significantly less space compared to traditional cabling solutions. This space-saving design not only maximizes the use of available area but also contributes to a cleaner and more organized installation. The aesthetic appeal of busbar trunking systems is an added advantage, particularly in modern architectural designs.

5. Ease of Installation and Maintenance

The modular nature of busbar trunking systems simplifies both installation and maintenance. Prefabricated components can be quickly assembled on-site, reducing installation time and labor costs. Additionally, maintenance tasks are straightforward, as individual sections can be accessed and replaced without disrupting the entire system.

Steps for Installing Busbar Trunking Systems

1. Planning and Design

The first step in installing a busbar trunking system is thorough planning and design. This involves assessing the power requirements of the facility and designing a system that meets these needs. Key considerations include the layout of the facility, the load distribution, and future expansion plans. Detailed planning ensures that the system is both efficient and scalable.

2. Selecting the Right Components

Choosing the right components is crucial for the success of the installation. This includes selecting the appropriate busbar material (copper or aluminum), enclosure type, and insulation materials. The choice of components should be based on the specific requirements of the application and the operating environment.

3. Installation of Support Structures

Before installing the busbar trunking system, it is essential to set up the support structures. These structures provide the necessary support for the busbar trunking system and ensure that it is securely mounted. Proper alignment and secure mounting are critical to maintaining the integrity of the system.

4. Assembling the Busbar Trunking System

Once the support structures are in place, the busbar trunking system can be assembled. This involves connecting the busbar segments and securing them within the enclosure. Attention to detail is crucial during this step to ensure that all connections are secure and that there are no gaps or misalignments.

5. Testing and Commissioning

After the busbar trunking system is assembled, it must be thoroughly tested to ensure that it is functioning correctly. This includes testing for electrical continuity, insulation resistance, and load capacity. Any issues identified during testing should be addressed before the system is put into operation.

6. Maintenance and Upkeep

Regular maintenance is essential to ensure the long-term performance and reliability of the busbar trunking system. This includes periodic inspections, cleaning, and testing. Maintenance tasks should be carried out by qualified personnel to ensure that the system remains in optimal condition.

Applications of Busbar Trunking Systems

1. Commercial Buildings

Busbar trunking systems are widely used in commercial buildings for efficient power distribution. Their flexibility and scalability make them ideal for office complexes, shopping malls, and high-rise buildings.

2. Industrial Plants

Industrial plants benefit from the robust and reliable nature of busbar trunking systems. These systems can handle high power loads and distribute electricity over long distances, making them suitable for manufacturing and processing facilities.

3. Data Centers

Data centers require reliable and scalable power distribution solutions. Busbar trunking systems provide the necessary flexibility to handle high power densities and dynamic load requirements, ensuring uninterrupted operation.

4. Healthcare Facilities

Healthcare facilities demand high levels of reliability and safety in their electrical installations. Busbar trunking systems meet these requirements, providing secure and efficient power distribution for hospitals and clinics.

5. Renewable Energy Projects

In renewable energy projects, busbar trunking systems are used to connect various components and distribute power efficiently. Their ability to handle high power loads and withstand harsh environmental conditions makes them suitable for solar and wind farms.

Conclusion

Busbar trunking systems offer a myriad of benefits, including efficiency, reliability, flexibility, safety, and ease of installation. Their applications span various industries, making them a versatile solution for modern power distribution needs. For expert assistance in implementing busbar trunking systems, Manikaran offers comprehensive Busbar Trunking and Transformer Installation Services to ensure optimal performance and compliance with industry standards. By understanding the installation process and the benefits of busbar trunking systems, businesses can make informed decisions to enhance their electrical infrastructure and ensure a reliable and efficient power distribution network.