Busbars are essential components of electrical systems, providing a reliable method of distributing electricity across different parts of a facility. While they are generally durable and efficient, there are several common problems that can arise over time. These issues, if not addressed promptly, can lead to system failures, inefficiency, or even safety hazards. In this article, we will explore the most common busbar problems and how to solve them, offering useful tips for ensuring the longevity and smooth functioning of your system. The services provided by Manikaran Enterprises for Busbar Trunking System Installation Services in India can be a key part of solving these issues effectively.

1. Overheating of Busbars

One of the most common problems faced by busbar systems is overheating. This issue can occur when the busbar is unable to handle the electrical load passing through it, causing excessive heat to build up. Overheating can also happen due to poor connections or insufficient maintenance, which prevent the system from functioning at its optimal level. When busbars overheat, the result can be melting insulation, potential sparks, or even fire in severe cases.

To solve this problem, it’s important to regularly inspect the busbar system and ensure that connections are properly tightened and maintained. Overheating can often be prevented by upgrading to a busbar system that can handle higher current loads. Hiring professional services like Manikaran Enterprises, known for their Busbar Trunking System Installation Services in India, ensures that the system is installed with the correct load capacity, reducing the likelihood of overheating and improving overall efficiency.

2. Corrosion and Oxidation

Corrosion is another issue that busbar systems often face, especially in environments with high humidity, salt, or exposure to chemicals. The process of corrosion happens when the surface of the busbar begins to deteriorate, forming rust or oxidation. This compromises the electrical conductivity, leading to inefficiency and potential failure of the system. In extreme cases, corrosion can result in short circuits or complete breakdowns of electrical components.

To prevent corrosion, it’s crucial to apply protective coatings and regularly clean the busbars to remove any contaminants that may accelerate oxidation. For environments where corrosion is unavoidable, selecting corrosion-resistant materials like aluminum or copper with protective coatings is a good solution. When you opt for Manikaran Enterprises for your Busbar Trunking System Installation Services in India, you can be assured that high-quality, corrosion-resistant materials will be used, increasing the longevity of your busbar system.

3. Mechanical Failures

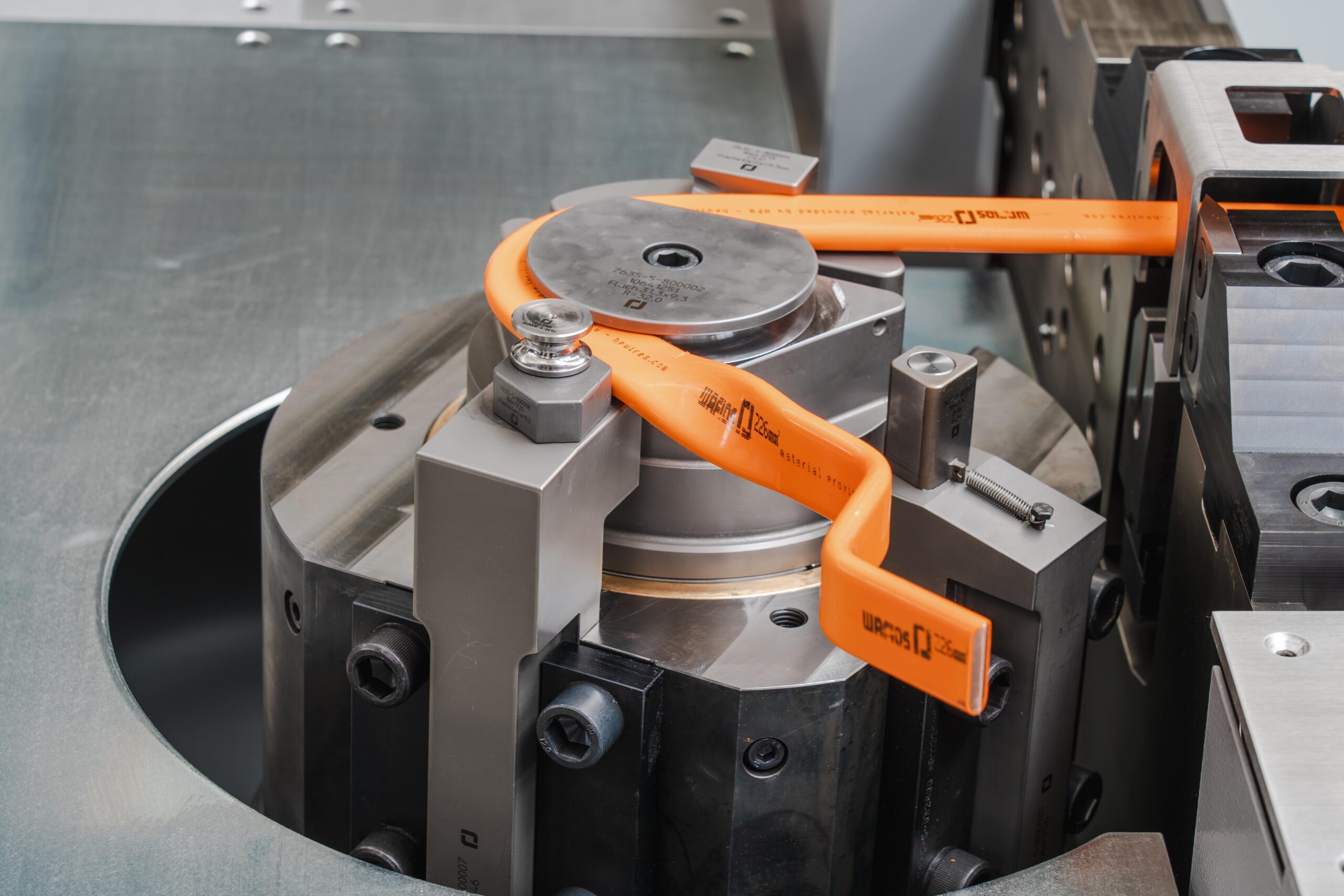

Mechanical failures in busbar systems, such as bending, loosening, or breaking, are often caused by poor installation practices or continuous physical stress. Over time, busbars that are not properly supported can experience stress that causes mechanical damage, leading to interruptions in the flow of electricity. Mechanical failures can also be triggered by vibration, especially in industrial environments where machines or electrical equipment are operating continuously.

To solve mechanical failure issues, the busbar system needs to be properly installed with adequate support and reinforcement. Ensuring that the busbar is securely mounted and that it has the right structural support can prevent damage from vibrations or physical stress. By engaging experts like Manikaran Enterprises for your Busbar Trunking System Installation Services in India, you ensure that your busbars are securely installed, minimizing the risk of mechanical failure and extending their lifespan.

4. Short Circuits

A short circuit in a busbar system is one of the most dangerous issues that can occur. It often happens due to insulation failure, improper connections, or accidental contact between busbars and foreign objects. Short circuits cause a sudden surge of current, which can damage electrical components, cause fires, and create serious safety hazards.

To prevent short circuits, it’s important to inspect the busbar system regularly, ensuring that insulation is intact and there is no risk of accidental contact with external materials. Correct installation of insulation, as well as the use of high-quality materials, can help to reduce the chances of short circuits. Choosing a reputable company like Manikaran Enterprises for Busbar Trunking System Installation Services in India guarantees that the system is installed according to the highest safety standards, minimizing the risk of electrical faults.

5. Overloading of Busbars

Busbars are designed to carry a specific amount of electrical current, and when they are overloaded, it can cause significant damage. Overloading typically occurs when the system is not properly sized to handle the electrical demands of the facility. This can lead to increased resistance, overheating, and eventual failure of the busbar system. In the worst-case scenario, overloading can cause complete electrical breakdowns.

The solution to overloading is to ensure that the busbar system is sized appropriately for the load it will carry. This can involve upgrading the system to a higher capacity, adding additional busbars, or redistributing electrical loads more evenly. With Manikaran Enterprises offering their Busbar Trunking System Installation Services in India, you can be assured that the installation will be tailored to handle the specific electrical requirements of your facility, avoiding the risk of overloading.

6. Improper Installation

Improper installation is a common cause of busbar problems. If the busbar system is not installed correctly from the start, issues such as poor connections, loose joints, or misaligned components can arise. These problems not only reduce the efficiency of the system but can also increase the risk of electrical failures and safety hazards.

To solve this issue, it’s important to choose a professional service for installation. Proper training, tools, and experience are required to install a busbar system correctly. Working with Manikaran Enterprises, which specializes in Busbar Trunking System Installation Services in India, ensures that the system is installed according to industry standards, reducing the chances of malfunction or system inefficiency.

7. Thermal Expansion Issues

As the busbar system operates, it can experience thermal expansion due to the heat generated by electrical current. If this expansion is not accounted for during installation, it can lead to joint failures, deformation of the busbar, or damage to surrounding components. Over time, these thermal issues can degrade the system’s overall performance.

To prevent these problems, busbar systems should be designed with thermal expansion in mind. Using flexible joints or creating gaps for expansion can help manage the impact of temperature changes. When you choose Manikaran Enterprises for your Busbar Trunking System Installation Services in India, you are assured that such factors will be carefully considered during the design and installation process to enhance the system’s longevity and efficiency.

8. Poor Electrical Conductivity

If a busbar system is dirty or covered in dust, dirt, or oxidation, the electrical conductivity will be reduced. This inefficiency can lead to power losses, overheating, and other operational issues. Poor electrical conductivity is one of the primary causes of inefficiencies in busbar systems, and it can seriously impact the system’s performance.

The solution to this problem is regular maintenance, which includes cleaning the busbar system to remove any buildup of dirt or oxidation. Proper insulation and the use of high-quality materials will also help in ensuring that the busbars maintain their conductivity. By opting for the Busbar Trunking System Installation Services in India from Manikaran Enterprises, you ensure that the system is installed using high-grade materials that will reduce the need for frequent cleaning and maintenance.

9. Voltage Drops

Voltage drops are another common issue faced by busbar systems, especially when the busbars are too long or have high resistance. Voltage drops occur when there is a loss of energy as electricity travels through the busbars, which can lead to inefficiency and potential damage to electrical equipment.

To resolve voltage drop issues, it is important to ensure that the busbars are appropriately sized for the electrical load and the distance the electricity must travel. Low-resistance materials, such as high-quality copper, should be used to minimize the loss of voltage. By working with experts like Manikaran Enterprises for your Busbar Trunking System Installation Services in India, you ensure that the system is designed with minimal voltage loss in mind, optimizing performance.

10. Frequent Maintenance Needs

Some busbar systems require frequent maintenance due to the use of subpar materials or improper installation. Frequent downtime for repairs or replacements can disrupt operations and increase overall costs.

Investing in high-quality busbar systems and professional installation services can help minimize the need for constant maintenance. By choosing Manikaran Enterprises for Busbar Trunking System Installation Services in India, you ensure that your busbar system is built to last with minimal maintenance, saving both time and money in the long run.

Conclusion

Busbar systems are critical for the efficient distribution of electrical power, but they are prone to certain problems. Regular inspections, proper installation, and high-quality materials are essential to maintaining the system’s reliability. By working with professionals like Manikaran Enterprises and opting for their Busbar Trunking System Installation Services in India, you can ensure that your busbar system is set up for long-term success, reducing the likelihood of issues and keeping your electrical infrastructure running smoothly.