In the realm of material science, the quest for innovative solutions to enhance thermal control properties remains incessant. One such breakthrough involves the utilization of Kyanite refractory geopolymers, revolutionizing various industries with their remarkable capabilities. This article delves into the multifaceted world of Kyanite powder and its pivotal role in shaping thermal control dynamics across diverse applications.

Unveiling the Power of Kyanite Powder

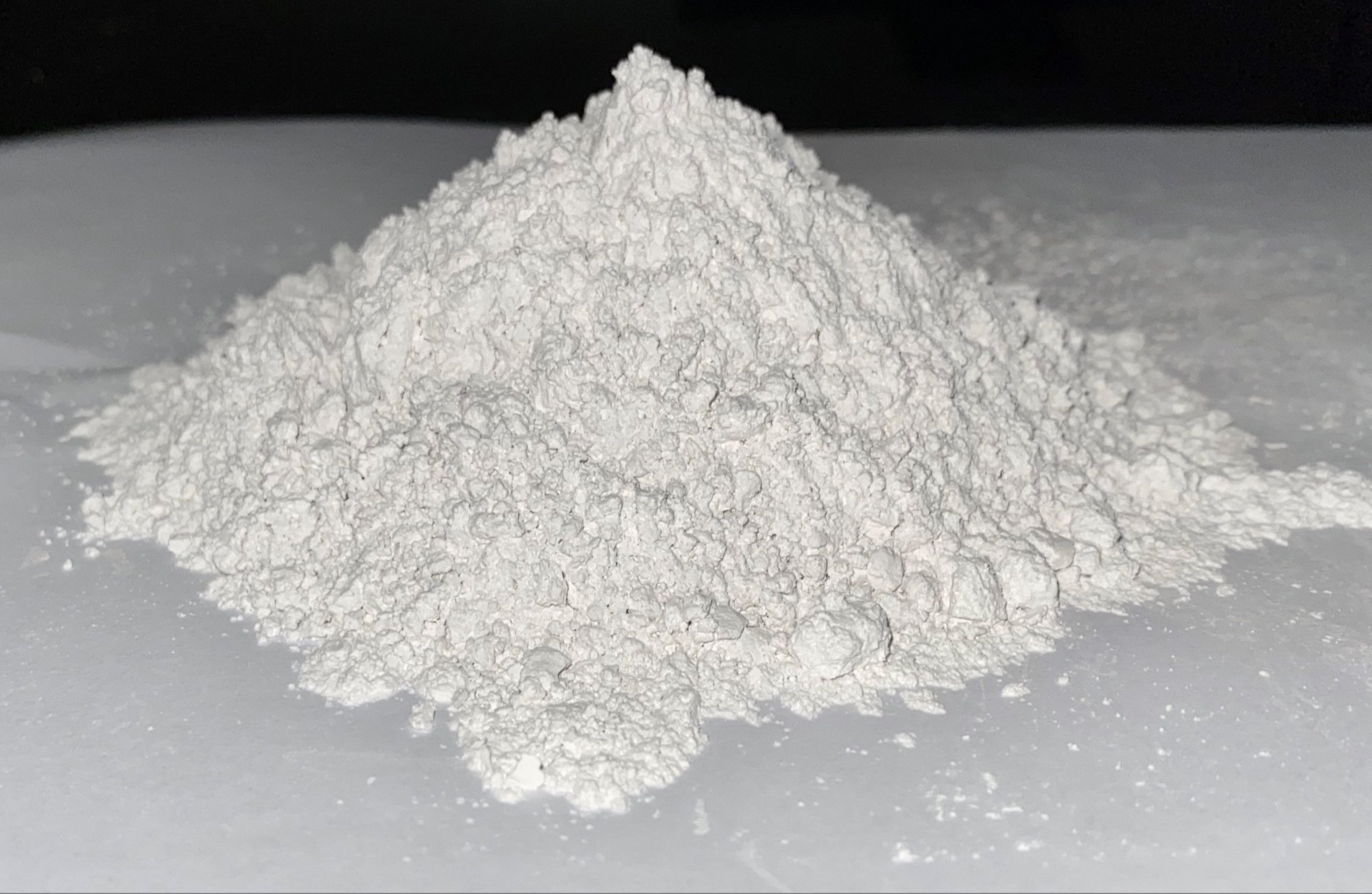

Kyanite powder, derived from the mineral Kyanite, boasts an impressive array of properties that make it an invaluable resource in multiple sectors. As an exporter of Kyanite powder in India, we witness firsthand its transformative potential. Its high thermal stability, low thermal expansion coefficient, and exceptional resistance to heat make it a coveted material for thermal management solutions.

Kyanite Powder in Electric Components

Within the Kyanite Powder in the electric component industry, maintaining optimal operating temperatures is paramount for ensuring efficiency and longevity. Kyanite powder emerges as a game-changer in this domain, offering superior thermal insulation and dissipation properties. By integrating Kyanite powder into electric components, manufacturers can mitigate heat-related issues, enhance performance, and prolong the lifespan of electronic devices.

Elevating Refractory Materials with Kyanite Powder

The refractory industry stands at the forefront of utilizing Kyanite powder to engineer high-performance materials capable of withstanding extreme thermal conditions. As a leading supplier of Kyanite powder in refractory material in India, we witness its integration into refractory linings for furnaces, kilns, and reactors. The addition of Kyanite powder enhances the thermal shock resistance and overall durability of refractory products, ensuring reliable operation in harsh environments.

Kyanite Powder’s Ceramics Revolution

Kyanite Powder in Ceramics manufacturing in India undergoes a revolution with the incorporation of Kyanite powder. Its unique combination of thermal and mechanical properties makes it an ideal additive for ceramic formulations. By harnessing the heat-resistant nature of Kyanite powder, ceramic products exhibit enhanced thermal stability and reduced susceptibility to thermal stress. This translates to superior performance in applications ranging from industrial machinery to consumer electronics.

Optimizing Thermal Control with Kyanite Refractory Geopolymers

At the intersection of innovation and sustainability lies Kyanite refractory geopolymers – a class of materials poised to redefine thermal control standards. By blending Kyanite powder with geopolymers, engineers unlock a synergistic blend of thermal insulation, mechanical strength, and chemical resistance. These advanced materials find applications across diverse industries, including aerospace, automotive, and construction, where precise thermal management is critical for operational efficiency and safety.

Driving Sustainable Solutions

Beyond its technical prowess, Kyanite powder’s utilization in thermal control solutions aligns with global sustainability objectives. By enhancing energy efficiency and minimizing heat-related wastage, industries can reduce their environmental footprint. As a responsible Kyanite powder exporter in India, we prioritize sustainable practices throughout the supply chain, ensuring that our products contribute to a greener, more sustainable future.

Innovation Through Collaboration

The journey towards unlocking the full potential of Kyanite refractory geopolymers requires collaborative efforts across academia, industry, and government bodies. By fostering interdisciplinary partnerships and supporting research initiatives, we can accelerate the development and adoption of next-generation thermal control solutions. Together, we pave the way for a future where thermal management challenges are met with ingenuity and resilience.

Conclusion

In conclusion, the integration of Kyanite powder into thermal control solutions represents a paradigm shift in material science. From electric components to refractory materials and ceramics, Kyanite powder’s versatility and performance elevate industry standards while driving sustainability goals. As we continue to explore the boundless possibilities of Kyanite refractory geopolymers, we usher in a new era of innovation, where thermal control is not just a challenge but an opportunity for transformative change.