Understanding PVC Shrink Labels

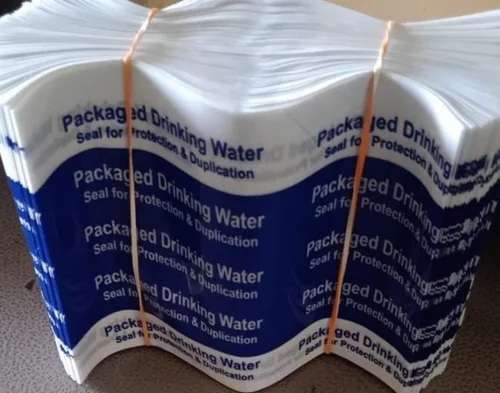

PVC shrink labels have revolutionized packaging solutions, particularly in the manufacturing hub of Jaipur. Known for their versatility and durability, PVC shrink labels are widely used across various industries, from food and beverages to pharmaceuticals and cosmetics. These labels conform perfectly to the shape of bottles, containers, and jars upon heat application, providing a snug fit that not only protects the product but also enhances its visual appeal.

In Jaipur, a city renowned for its craftsmanship, the production of PVC shrink sleeves has reached new heights. Companies like Shree Tirupati Balaji have perfected the art of manufacturing these labels with precision and quality. The process involves meticulous attention to detail, ensuring that each label meets stringent standards of durability and clarity.

Quality Manufacturing Processes

At Shree Tirupati Balaji, the manufacturing of PVC shrink cap neck seals and bottle seals is a blend of advanced technology and traditional craftsmanship. These seals play a crucial role in preserving the freshness and integrity of products, safeguarding them against tampering and environmental factors. The production begins with high-grade PVC materials that are carefully selected for their strength and elasticity.

State-of-the-art machinery is employed to precisely cut and shape the PVC shrink labels, ensuring consistency in size and thickness. The labels are then printed with vibrant colors and intricate designs, showcasing the brand identity with clarity and finesse. Each step of the manufacturing process is closely monitored to maintain the highest standards of quality control, adhering to international packaging norms.

Innovations in Packaging Solutions

Jaipur’s emergence as a hub for PVC shrink label manufacturing has been driven by continuous innovation and adaptation to industry trends. Companies like Shree Tirupati Balaji invest significantly in research and development to introduce new packaging solutions that meet evolving consumer preferences and regulatory requirements.

The versatility of PVC shrink sleeves allows for creative packaging designs that differentiate brands on store shelves. Whether it’s a unique bottle shape or a specialized container, these labels conform seamlessly to the packaging, providing a 360-degree branding opportunity. Brands can leverage this flexibility to enhance product visibility and consumer engagement, ultimately driving sales and brand loyalty.

Conclusion

In conclusion, mastering the art of PVC shrink labels requires a deep understanding of materials, manufacturing processes, and market dynamics. Companies in Jaipur, such as Shree Tirupati Balaji, exemplify this mastery through their commitment to quality and innovation. By continually pushing the boundaries of packaging technology, these companies not only meet industry standards but also set new benchmarks for excellence.

For businesses looking to elevate their packaging strategy, PVC shrink sleeves offer a compelling solution that combines functionality with aesthetic appeal. Whether you’re in the food and beverage industry or the pharmaceutical sector, investing in high-quality PVC shrink cap neck seals and bottle seals can significantly enhance your brand’s perception and consumer trust.

Incorporating multimedia elements like product images and videos can further enrich the understanding of PVC shrink labels and their manufacturing process. By embracing these innovations, businesses can stay ahead in a competitive market landscape while delivering superior products to consumers worldwide.