Coated calcite plays a crucial role in modern construction and building materials. Understanding its significance helps in recognizing why this component is so essential in achieving quality and durability in various construction applications.

What is Coated Calcite?

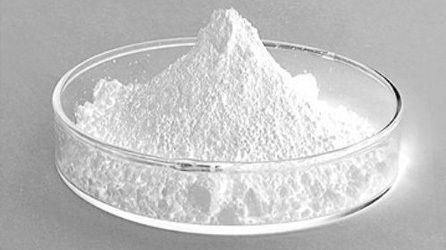

Coated calcite is a refined form of calcium carbonate, a naturally occurring mineral. The “coated” aspect refers to the process where the calcite particles are coated with special substances to enhance their performance in different applications. This coating improves the properties of the calcite, making it more effective in various industrial uses.

Advantages in Building Materials

In the construction industry, coated calcite is valued for several reasons:

- Improved Durability: Coated calcite enhances the durability of building materials. When used in products like cement or plaster, it improves the strength and longevity of the final product. This added durability is crucial for ensuring that buildings can withstand various environmental conditions.

- Better Workability: The coating on the calcite particles helps in achieving better workability of the materials. For instance, in cement and concrete, coated calcite helps in improving the mixability and consistency, making it easier to work with and apply.

- Enhanced Aesthetics: Coated calcite is used in paints and coatings to achieve a smooth and even finish. The coating helps in reducing the visibility of imperfections and provides a more aesthetically pleasing result, which is especially important in architectural finishes.

- Cost Efficiency: Using coated calcite in building materials can be cost-effective. Its properties help in reducing the amount of other, more expensive additives needed, thereby lowering the overall cost of the materials.

The Role of Calcium Carbonate Powder

Calcium carbonate powder is a key component in the production of coated calcite. This powder is processed and refined to achieve the desired purity and particle size, which are essential for the coating process. The quality of calcium carbonate powder directly affects the performance of the coated calcite in building materials.

Choosing a Coated Calcite Manufacturer

Selecting a reliable coated calcite manufacturer is important for ensuring high-quality building materials. A good manufacturer will use advanced technology and processes to produce calcite that meets industry standards. This ensures that the coated calcite used in construction will deliver the expected benefits in terms of durability, workability, and cost efficiency.

When choosing a manufacturer, consider factors such as their reputation, the quality of their products, and their adherence to industry standards. This will help in sourcing the best materials for your construction needs.

Conclusion

Coated calcite is an important material in the construction industry due to its numerous benefits. From improving the durability and workability of building materials to enhancing their appearance and cost efficiency, coated calcite plays a significant role in modern construction. Understanding its importance and the role of calcium carbonate powder in its production can help in making informed choices for building projects.